How CNC Technology is Revolutionising Cut-to-Size Cabinetry in Commercial Joinery

CNC technology is fundamentally changing the commercial joinery industry by making the production of cut-to-size cabinetry faster, more accurate, and more efficient. For project managers, designers, and builders, this means higher-quality results, reduced lead times, and less on-site waste.

Why is CNC Technology More Effective than Traditional Woodworking?

The primary advantage of using CNC technology over traditional woodworking methods lies in its precision and automation. Traditional methods rely on manual measurements and cuts, which are prone to human error, leading to material waste and inconsistencies. CNC technology eliminates this risk by using a computer to precisely control the cutting tools.

Precision and Consistency: A CNC machine can replicate a design with perfect accuracy, ensuring every cabinet part is identical. This consistency is crucial for large-scale projects, where thousands of panels need to fit together seamlessly.

Speed and Efficiency: CNC machines can work continuously and at a much faster pace than a person. This significantly reduces production time for commercial joinery projects.

Reduced Waste: By nesting parts efficiently on a sheet of material using specialised software, CNC technology minimises offcuts and material waste, leading to cost savings.

Complex Designs: CNC machines can easily create intricate cuts, complex curves, and precise joinery that would be difficult or impossible to achieve with traditional hand tools.

How Does CNC Cutting Work for Cabinetry?

The process begins with a digital design. A joiner or designer creates the cabinetry components in a CAD (Computer-Aided Design) software program. This digital file is then converted into a set of instructions, or G-code, that the CNC machine can understand.

The CNC machine's computer reads the G-code and directs the cutting tool—usually a router bit—to move along the X, Y, and Z axes. The machine cuts all the required parts from a large sheet of material like MDF, plywood, or particle board. The result is a perfect, ready-to-assemble flat-pack kit, complete with pre-drilled holes for hardware and joinery.

New Developments in CNC Technology

The technology is always evolving, with new developments making CNC even more powerful for joinery:

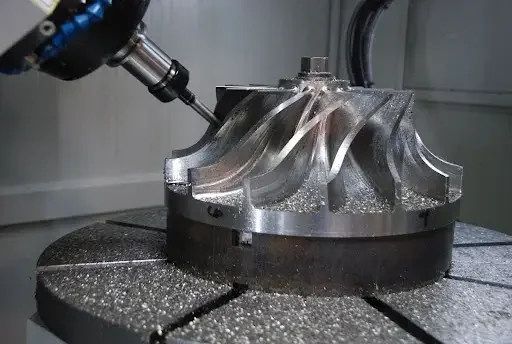

Multi-Axis Machining: While 3-axis machines are common, 5-axis and even 9-axis machines are becoming more prevalent. These advanced machines can cut complex, organic shapes with a single setup, reducing production time and increasing precision.

Automated Tool Changers: Modern CNC machines can automatically switch between different cutting tools, drills, and bits, further speeding up the production process and allowing for a wider range of operations without manual intervention.

Integrated Software Solutions: Advanced software can now not only design the cabinets but also automatically generate the cut files, track material usage, and manage the entire production workflow from design to delivery.

Why is CNC Used in Manufacturing?

CNC technology is a cornerstone of modern manufacturing because it offers a perfect blend of speed, accuracy, and scalability. It allows a business to produce high-quality products consistently, whether it’s a single bespoke piece or thousands of identical parts. For commercial joinery, this means a factory can operate and scale up as one production unit, based on a uniform process and centralised software.

This is where a manufacturing partner like Cutshop® comes in. We provide businesses with extra capacity for project overflows or machine breakdowns. Our centralised software programming and consistent machinery set-up across our Auckland and Hamilton factories ensure that you get the same precision and quality every time, without the responsibility and expense of managing your own equipment.

When you partner with us, you can focus on the more profitable and enjoyable aspects of your business, knowing the manufacturing is handled with precision.