Which materials to choose

How to choose the right cabinet materials for your home project.

With any home renovation project, understanding your cabinet materials is a necessity as the right cabinetry can make a room look a million dollars. High-quality cabinetry will determine the longevity of its usage and enhance the value of your home and is therefore important to get right.

Whether you are renovating your forever home kitchen or doing a quick bathroom upgrade there are great cabinet choices for any budget.

But where do you start?

MDF, plywood, or particle board, which do you choose?

Getting to know your substrate.

A substrate refers to the different types of engineered wood products used in a variety of applications, from home construction to commercial building to industrial products. Also known as composite wood, man-made wood or manufactured boards, the most common composite boards are MDF, Plywood and Particleboard.

MEDIUM DENSITY FIBREBOARD

MDF is a strong, durable and dense material created using recycled hardwood and softwood materials. Broken down into fine particles, it is then combined with wax and a resin binder before applying high temperature and pressure to create the finished product.

Mainly used for kitchen cabinets, MDF offers greater versatility and are easier to customize offering much more choice when it comes to creating the dream kitchen

Benefits of MDF

Cheaper than plywood

The surface is smooth making it great for painting.

It is consistent throughout, so edges appear smooth.

You can use a router to create decorative edges

It is easy to cut with a detailed design using a scroll saw, jigsaw or band saw.

Disadvantages of MDF

MDF can soak up water and will swell like a sponge if not sealed correctly.

It can be heavy which can make it difficult to work with.

MDF is often the cabinet material of choice for kitchens and bathrooms, you just need to remember to make sure that the MDF you choose is highly water-resistant.

Stylish kitchen cabinetry with a satin finish on standard white MDF in Jason Bagnall’s Auckland home.

PLYWOOD

Plywood is an engineered wood product made of three or more thin layers of wood bonded together with an adhesive. Each layer of wood is placed at right angles to the adjacent layer in order to reduce shrinkage and improve its overall strength.

Advantages of plywood

It looks great, either with a good quality veneer or solid wood cover especially with exposed edges.

It’s strong due to the criss-cross nature of its layered construction.

It’s durable and lightweight

It can hold screws well.

Plywood is resistive to shrinking, warping, swelling and cracking.

Disadvantages of plywood

It is more expensive than MDF

The edges may need to be finished with a veneer or laminate if you’d like to hide the layers of ply.

It can be damaged by water if not treated and sealed properly.

Popular in kitchens, bathrooms, laundries and garages due to it’s strong and durable quality, plywood hits the spot when it comes to cabinet design.

Striking black plywood kitchen cabinets

PARTICLEBOARD

Otherwise known as chipboard, particleboard is made up of particles or chips of wood held together by glue, then pressed under heat.

Advantages of Particleboard

It has a smooth finish allowing decorative laminates and other finishing materials to make the product look amazing.

Particleboard is budget-friendly and is by far the cheapest option out of MDF and Plywood.

It is thought to be more environmentally friendly as it is made of the scraps of other lumber products.

Light in weight so It is easy to transport and handle.

Disadvantages

Not as strong as other materials such as MDF or Plywood.

Will warp in moisture and humidity.

Cannot support heavy loads.

Due to the fine particles, it does not hold screws well.

Most materials boards are presented with a veneer, film or a colour laminate which are fused by heat and pressure to your chosen substrate. Whatever your design vision is, there is a look for you. The options are endless.

Choosing between laminate and veneers.

LAMINATE CABINETS

Laminate cabinets have garnered a mixed reputation over the years. The 1970s laminate reigned supreme with bold colours and crazy designs, however, over the last two decades laminates have come on leaps and bounds in design, durability and choice.

Typically created by three resin-saturated layers: either a base layer of paper, a printed and coloured layer (which may look like wood) and a protective transparent layer fused together with heat and pressure to the substrate below.

The interior of laminate cabinets is composed of whichever cabinet material you have chosen in accordance with your budget.

Know your HPL from your Melamine

Have you heard the terms but are unsure of the differences? Similar in the sense they are both a type of laminate, High-Pressure Laminate (HPL) is composed of 6-8 layers of printed paper bonded together under very high heat and pressure. The results are a very durable surface with high resistance to knocks and scrapes.

Melamine is low-pressure laminate (LPL), typically composed of 1-2 layers of printed paper pressed onto your chosen substrate and sealed with resin under heat and pressure. Melamine can often be found in a large array of patterns and produces the closest look to real timber without the cost of real timber. Melamine is typically the more cost-effective option compared to HPL.

Both HPL and Melamine are great laminates and can be found in a large variety of colours and choices.

So why should you consider laminate cabinets for your cabinet doors?

The answer is simple; they are durable, can be found in a huge variety of styles and colours, easy to clean, should last a lifetime and can easily be painted over should your taste and style change.

New Zealand based companies such as Laminex and Prime Panels hold a vast range of choice when it comes to laminate cabinets, and are great places to head to for inspiration.

WOOD VENEER CABINETS

Wood veneers are rising in preference as the go-to for interior cabinetry. The veneer is a very thin slice of solid wood that is laid on top of different types of engineered wood, such as MDF, Plywood or Particleboard to give a solid wood aesthetic without the accompanying price tag of solid wood.

Wood Veneer is a great choice for natural timber kitchen cabinet design and can be mixed with actual solid wood countertops or kitchen island base cabinetry.

A beautiful combination of MDF and Wood Veneer in Neil and Linda Forrester’s kitchen in their Howick home.

Top tips for knowing your veneer types and styles.

As a natural material and a renewable resource, Wood Veneer has intricate grain, rich colours, warmth, beauty and individuality in its look. Due to this quality, it is rare to get uniformity in each veneer inventory so expect to have slightly different hues and grain shapes throughout the whole project.

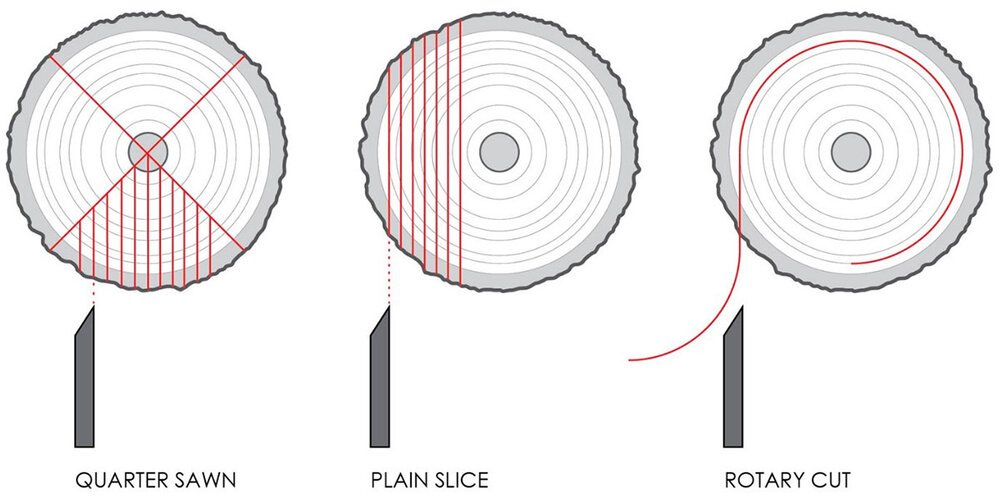

The way the wood is sawn or sliced will produce completely different grain characteristics, and along with the way the material is layered will lead to thousands of variations and design possibilities.

There are four different types of veneer cut:

Veneer rotary cut refers to the position of the wood in the lathe which is turned against a razor-sharp blade, imagine a large pencil sharpener at work. The result is an exceptionally wide piece of veneer.

Veneer Plain Cut is when a flat piece of lumber is passed lengthwise through a knife that is stationary.

Veneer Quarter Cut occurs when the timber is cut into quarters first before being sliced in an up and down motion. The result is a straighter grain without the growth rings.

Veneer Crown Cut is a widely used method of plain slicing half a log against a knife in an up and down motion. This creates a straight grain with cathedral peaks producing a very natural look.

Understanding the cuts in veneer means you can approach the design of your cabinetry project with greater imagination and creativity.

One thing to remember when considering a wood veneer as your cabinet design choice is that wood veneers do need more maintenance than laminates due to their porous nature. They can absorb water which may lead to warping and so will benefit from a polish from time to time.

The power of paint.

For those design ideas where Laminate or Wood Veneer just doesn’t offer the aesthetics you are after, spray painting MDF is a great option.

The beauty of this is that you can order MDF cabinetry that can be spray-painted in your favourite colour and engraved, using a router, with a pattern of your choosing. Making for truly original and unique custom cabinetry that is effective, affordable and offers you a huge variety of choice.

The final choice.

If you find yourself still unsure of which cabinet material is right for your project, get in touch with one of our expert team members who will guide you through the process.

They will use their knowledge and expertise to work alongside you to ensure you get the best product for your budget. Our goal is a happy customer, satisfied with the quality of their new cabinetry.

Get in touch with Cutshop® to find out more or book an appointment.