What is a CNC Cutter?

A CNC cutter is a machine that uses a computer to precisely control cutting tools. The acronym CNC stands for Computer Numerical Control, which refers to the automated control of machines by a computer. Instead of a person manually guiding the tool, the computer reads a program of instructions and directs the machine's movements, allowing for highly accurate and repeatable cuts. This technology is widely used in manufacturing for tasks that require precision, speed, and efficiency.

The cutter itself can be a variety of tools, such as a spinning router bit, a drill, or even a blade. The CNC machine moves this tool along multiple axes (typically X, Y, and Z) to cut, shape, and engrave materials. The process starts with a design created in a software program, which is then translated into a set of coordinates and commands that the CNC machine understands.

What is a CNC machine used for?

CNC machines are incredibly versatile and are used across numerous industries, from aerospace to furniture making. Their primary use is for the fabrication and manufacturing of parts and components. For example, a CNC cutter can be used to:

Create intricate parts for machinery.

Cut out kitchen cabinet panels and shelving with perfect precision.

Engrave detailed designs on wood or acrylic.

Fabricate signage and architectural models.

Produce moulds for casting other materials.

The machine's ability to handle complex geometries and repeat a task thousands of times without losing accuracy makes it essential for mass production and custom projects alike.

What is the difference between a CNC cutter and a laser cutter?

While both CNC cutters and laser cutters are controlled by a computer and used for precision cutting, their methods are fundamentally different.

CNC Cutter (Router/Mill)

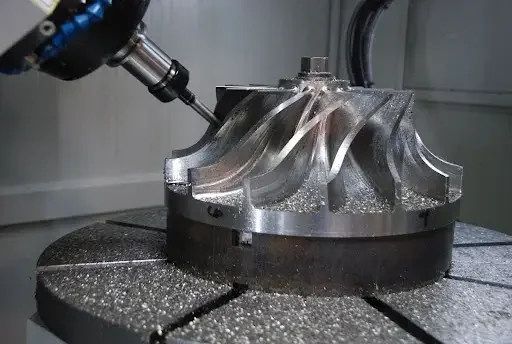

This type of machine uses a physical, rotating cutting tool to remove material from a workpiece. It's a subtractive process that involves direct contact with the material. This makes it ideal for thicker materials like solid wood, MDF, and aluminium, as it can cut deeply and create 3D shapes.

Laser Cutter

A laser cutter uses a focused, high-powered laser beam to melt, burn, or vaporise material. It's a non-contact process. Laser cutters are excellent for intricate, fine detail work and are best suited for thinner materials such as plywood, acrylic, paper, and fabrics. They typically excel at 2D cutting and engraving.

In essence, a CNC cutter is like a very precise, automated router or drill, while a laser cutter is like a very powerful, automated light beam.

New Developments in CNC Technology

The world of CNC technology is constantly evolving. Some of the latest developments include:

Advanced Software: More user-friendly software and cloud-based platforms are making CNC technology accessible to a wider range of users, from hobbyists to large-scale manufacturers.

Multi-Axis Machining: While 3-axis machines are common, 5-axis and even 9-axis machines are becoming more prevalent. These advanced machines can cut complex, organic shapes with a single setup, reducing production time and increasing precision.

Increased Automation: Integrating CNC machines with robotics for tasks like material loading and part unloading is creating fully automated production lines.

Smart Machines: Modern CNC machines are equipped with sensors and IoT (Internet of Things) technology. This allows for real-time monitoring, predictive maintenance, and data analysis to optimise performance and prevent downtime.

These innovations are making CNC technology faster, more efficient, and more versatile than ever before. For a DIYer looking to bring their project to life, these advancements mean even greater precision and the ability to create complex designs with less effort.

Let Cutshop® bring your project to life!

While understanding the technology is interesting, the real value lies in how you can use it to your advantage. Why invest in expensive machinery when you can partner with a team that has the technology ready to go?

At Cutshop®, we use advanced CNC cutting services to produce stunning kitchens, laundry cabinets, shelves, and storage solutions that are custom-made to fit your space and requirements. Forget cookie-cutter designs and bring your unique vision to life with our precision custom-cut flat-pack cabinetry—delivered with all the construction holes and hardware you need.