Every step of the way.

Cutshop client breaks into US market.

An innovative idea, some clever engineering and excellent execution have opened the door to an export market in the USA for one of Cutshop’s Auckland-based clients.

Glen Reid, the brains behind Futura Trailers, started out manufacturing bespoke trailers seven years ago. He and his team developed their game-changing low loading mechanism for enclosed trailers before specialising in open trailers for transporting race cars.

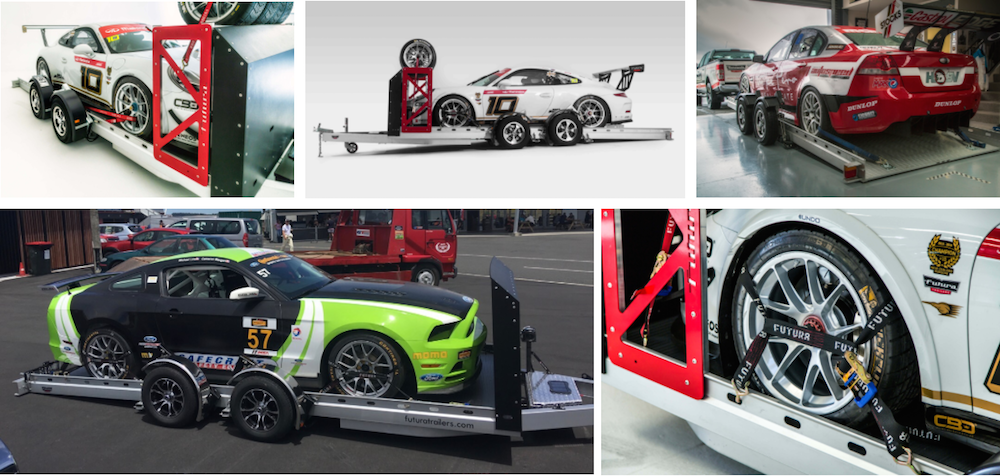

The design of the single and twin axle Futura trailers makes it easy to drive low profile racing cars on and off the aluminum trailer deck, without removing parts or risking damage to the vehicle.

“We developed some simple lifting technology for safe and easy loading directly from the ground,” said Glen. “The low approach angle onto the aluminum trailer deck makes the design perfect for long, low profile cars like Porsches. We learnt from the market while building one-off designs and, after some analysis, we realised that 50% of our sales came from open racing car trailers. So, at the end of 2015, we decided to specialise.”

The best trailer in the world

Glen started looking outside New Zealand for a bigger market for the open trailer, dubbed by two-time Indianapolis 500 winning race car driver Al Unser Jr. as ‘the best trailer in the world’. Using Facebook marketing and word of mouth referral, Futura trailers quickly started to cause a few ripples in racing circles.

“The end-product has been a real hit in the USA because of its unique engineering mechanism – there’s nothing quite like it out there,” confirmed Glen. “People see our trailer at the track and call us the next day. It really is a product that sells itself.”

Glen met and personally delivered the first container of 12 trailers to hit American shores. “We used the opportunity to meet our customers, find out more about the market and test our delivery processes.”

This made a great first impression. A year on, Futura now ships a container a week to the USA and momentum is building.

Agile, flexible partnership.

Behind the scenes, Cutshop is working alongside Futura Trailers to produce the almost indestructible, thermoplastic stone guard that sits at the front of each trailer to protect the high-value vehicles from damage while they are in transit.

“Cutshop was always flexible enough to make whatever I wanted and they saved us having to buy a machine to do it ourselves. Another great thing was that Cutshop charged a fixed cost per sheet which made great commercial sense for us while we were developing our product. Often the design would change from one order to the next and Cutshop was able to accommodate this, rather than demanding scale.”

One of the things that Glen values about his relationship with Cutshop is the way in which the two businesses have grown together. In the early days, Cutshop would cut ACM (aluminum) panels to make the box enclosure trailers.

Over time, Glen and his team refined their product and started ordering multiples of a single design. “There were never any issues with the cutting,” he added.

When Cutshop opened a new franchise, closer to Futura Trailers, Glen moved his business from Mount Wellington to Auckland’s North Shore. With all Cutshop franchises having the same machinery, software and capability, there was no disruption to business.

Cutshop now holds stock for Futura and orders have grown from three or four a month to 30 or 40.

Custom-made packing crate

To make exporting the trailers as efficient and risk-free as possible, Glen spent a week designing a custom-made packing crate to house the parts. Each container can accommodate 12 trailers leaving only millimeters of space to spare, so there is no room for error.

The design for the plywood packing case was then passed on to Cutshop to produce templates. The crates are then packed, stacked on top of each other and bolted together to protect the gear and ensure that it arrives in perfect condition.

Glen now spends half the year in the USA and he’s looking at the possibility of shipping parts and assembling overseas by the end of 2017. As the business has grown and developed, Cutshop has been there every step of the way.

“Cutshop offer us the ability to do exactly what we want. They have the expertise, the design software to take drawings to final templates and the CNC machines. They save us the capital investment in machinery by providing us with a factory — and their part of our production process comes down to a fixed cost per sheet, so there are no surprises. They are exactly the kind of business that we want to partner with because they see the big picture.

They are a supplier that we can really rely upon. Accurate, agile and reliable.”