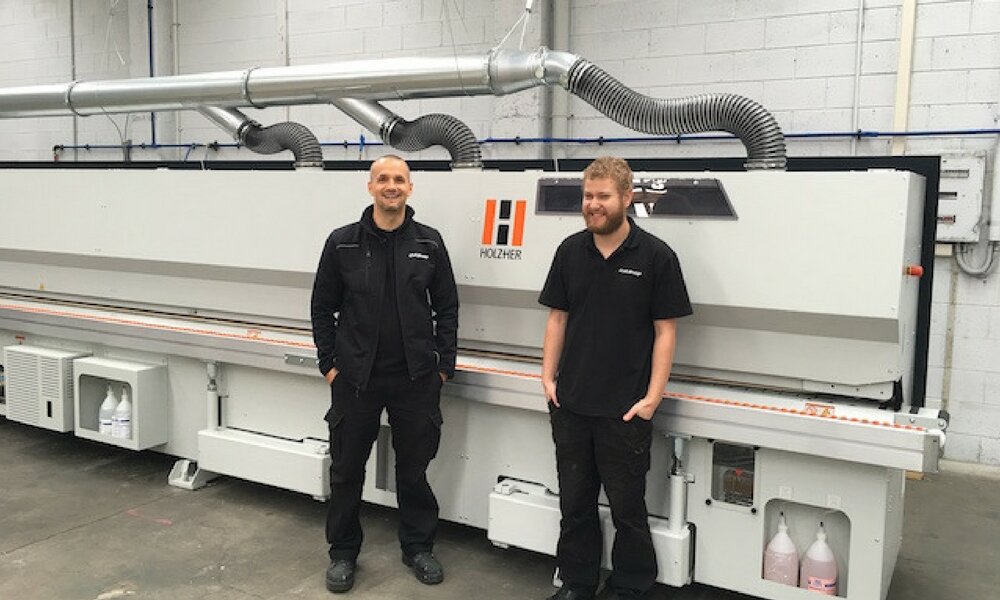

Edge banding machine

Who needs an edge banding machine, anyway?

Are you building your own kitchen or bathroom cabinets? If so, you may need to apply edge tape to your doors and exposed panels. If you’re a DIYer, though, that can be a problem. In this article, we explain why you needn’t worry.

In case you don’t know…

Unless you are using materials such as solid wood or lacquered MDF, you will probably require edge banding. For example, melamine panels have thermally fused, resin-saturated paper bonded onto particle board, which are great because they are durable, easy to clean, and there are many kinds of finishes available.

However, with both, the core material is left exposed on the edges when panels are being cut into workpieces. So, unless the workpiece edges are inside the cabinet and not visible, they need to be covered up. This is why:

Your cabinets would look pretty awful with exposed particle or MDF board.

If the edges aren’t sealed, moisture can get in and cause the board to blow out of shape.

What can you do?

Well, in a home environment you can apply edge-tape by hand using an iron. This can be tricky, though - particularly if you have a lot to do, and achieving nice and tidy results can be difficult. An edge banding machine will produce the best results but how can you get hold of one?

Not a problem - here at Cutshop we have all the machinery you need to make your DIY project possible. This includes CNCs and, you guessed right, edge banders.

The grandaddy of edge banding machines

And we don’t use just any old edge banders.

Our Holzher Lumina 1586s are state-of-the-art machines imported from Europe with three glue options:

EVA (standard)

PUR (heat & water resistant)

Laser (L-tronic technology is similar to a laser beam, not hot air).

No glue lines

The laser technology is pretty exciting. No glue required - so there’s no glue lines and a premium finish with a high-gloss, paint-like quality.

It’s pretty easy

At Cutshop, we are available to cut, drill and edge material for DIYers and tradies. Just draw up your cabinets, and we will produce a cutting list - if you can draw it, we can certainly make it happen.

If you’d like to learn more about how Cutshop can make your DIY project a reality, please get in touch.